Data logging can be the key to true energy savings

Rotary vane compressor manufacturer Mattei is highlighting the importance of data logging for compressed air users to ensure the system is running as efficiently as possible, following anecdotal evidence showing many businesses have inefficient systems. Saving energy and money has never been so important, so by ensuring it is delivering the best results, end users can potentially reap financial rewards by reducing unnecessary usage.

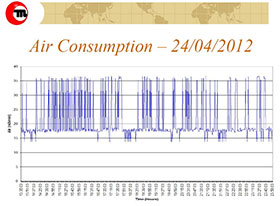

Many companies are operating with inefficient or unsuitable air compressors and data logging can help to identify these mistakes. Mattei always recommends a preliminary data logging exercise to evaluate air needs and the efficiency of the system, and can undertake this for customers. This is worked out by recording and measuring air consumption profiles over a seven day period and providing the exercise is carried out in a typical week, the results can be extremely insightful.

Andy Jones, General Manager of Mattei, says: "Data logging is the best way to identify whether changes to the system or investment in new equipment can result in energy savings. This is why Mattei always recommends them to any customers who are planning to upgrade or change their system - so they can be confident they are doing the right thing.

"We have seen a number of cases where data logging can result in significant energy and financial savings. Recently, one customer saw an annual saving of £26,000 following a Mattei data logging exercise that identified the two compressors installed could be replaced with new more efficient machines with a payback of just two years.

"However, in some cases, data logging actually reveals it would be inappropriate to replace the existing compressor - which means the customer doesn't spend money unnecessarily."

Data logging also identifies whether there is a constant or variable demand for air. Variable speed compressors have become popular in recent years because of their ability to save energy, but they aren't always the right solution.

Andy explains: "A variable speed drive will only save energy if there are peaks and troughs in the demand for air. This sounds common sense, but it's surprising how many variable speed machines are incorrectly specified for applications where demand is constant. An energy efficient compressor can only be efficient if it actually suits the needs of the application."

Finally, it is not uncommon for companies to still be using compressors that were installed many years ago, even though their air usage has dramatically reduced since. Andy continues: "In this situation data logging would identify the current usage, highlighting an opportunity to install a more suitable machine and achieve savings.

In addition, as technology has moved on, today's compressors are on the whole significantly more energy efficient. We often hear that companies feel they can't afford to replace a compressor, but with the potential for very high savings, we believe businesses should consider the long-term and perhaps they can't really afford not to change them."

For any company that does discover replacing their compressor is the best course of action, an interest free loan from the Carbon Trust Loan could help with the cost. Mattei can help customers with this relatively simple process.

For more information about Mattei and its ranges of compressors, Contact Us.

Back to archived news